- Home

-

About Us

The medium environment is your loyal partner

- News&Press

The medium environment is your loyal partner

- Achievements

The medium environment is your loyal partner

- Business

The medium environment is your loyal partner

- HR

The medium environment is your loyal partner

- Contact Us

The medium environment is your loyal partner Technical achievementsCement kiln co-processing industrial waste and hazardous waste

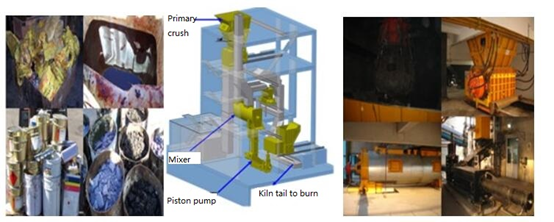

Technical achievementsCement kiln co-processing industrial waste and hazardous waste1. Semi-solid system

A semi-solid system can break, moreover, slurry mix the industrial sludges, waste residues and waste water. Then pump them into the kiln high temperature for incineration. Semi-solid system is applicated in rapid disposal of the hazardous waste with high moisture, high viscosity, high solid content or a small amount of sludge waste which has.

The existing technology and equipment can meet the disposal requirements that 0.3 to 30,000 tons/year.

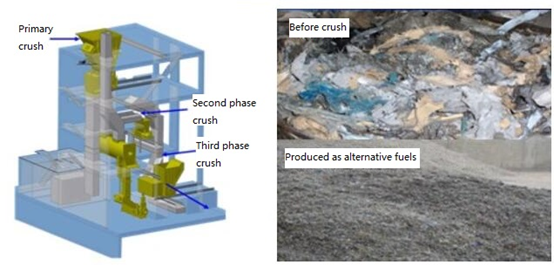

2. Alternative fuel preparation system

An alternative fuel preparation system that can use the combustible industrial wastes and the screen residues of household waste which are of heat value and low moisture as alternative fuels.

The technology and equipment we known can treat the waste 0.5 to 50,000 tons/year.

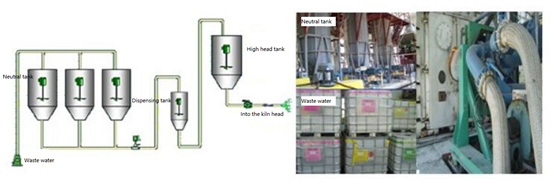

3. Wastewater treatment system

Wastewater treatment system pre-treat the waste acid, waste alkali, organic solvents, emulsions and mineral oil, which makes them can be treated or combusted at the area with high temperature and rich oxygen of the cement kiln.

The technology can treat waste 0 to 2 tons/year.

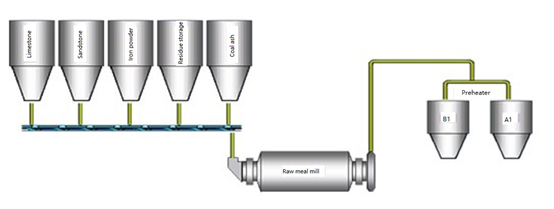

4. Residue incineration system

Residue incineration system use the incineration residue of the household waste as alternative raw material (alternative of silicon or aluminium raw materials). According to the harmful components of raw materials and waste composition to allocate the incineration scale.

The technology and equipment are of the capacity that treat waste for 40,000 tons/year.

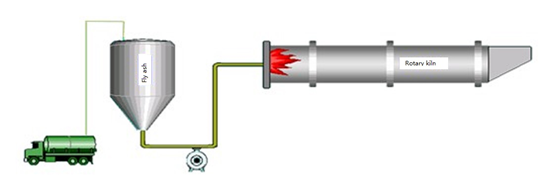

5. Fly ash handling system

The fly ash handling system that can spray the hazardous fly ash into kiln through the multi-channel burner. It burned in the kiln to eliminate its harm and to achieve large-scale cement kiln disposal.

The waste pre-treatment technology which is mainly on waste crusher can handle the different waste for 10 ~ 1000t/d.

Friendship link: China timber stock China timber internationalCopyright:中材国际环境工程(北京)有限公司ICP:京ICP备11045707号-1 - News&Press